How is a carbon negative carpet tile even possible? Our interview with Mikhail Davis, Interface’s Director, Global Market Sustainability, explores recent innovations in products & process.

Interface has a 25+ year commitment to sustainability, becoming a restorative business that creates economic value in a way that also creates environmental value. Today, Interface is focusing on carbon reduction, not offsets. Working toward achieving its verified science-based targets by 2030, it has a goal to become a carbon negative enterprise by 2040.

A Carbon Negative Enterprise by 2040

WDM: The story of Interface’s 30 year transformation into the leading sustainable player in the carpet tile industry is legendary. Please walk our readers through your significant environmental innovations in the last 5 years with factory operations, product development and the supply chain.

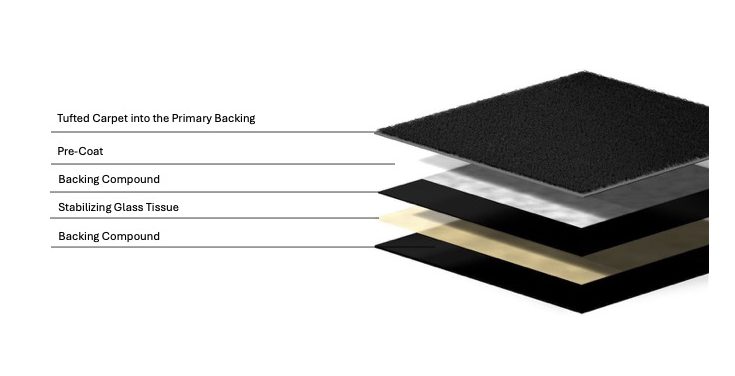

Mikhail Davis: In light of our shift from Mission Zero (manufacturing products with zero environmental impact) to our new goal to be a Carbon Negative Enterprise by 2040, we have invested over $100M since 2019 in technologies that allow us to make our products from materials made from carbon that would otherwise end up in the atmosphere contributing to global warming. Examples of this include the creation of a new carbon negative bio-based carpet tile backing (“CQuest™Bio“) that is now our standard in Europe and a standard alternate in the Americas.

CQuest™BioX backing holds so much carbon that it can make up for all carbon emitted in the supply chain and manufacturing process for carpet tile. Using many sources of carbon storing material, the Interface design team built on the formula for CQuest™Bio to achieve this major milestone.

The world’s first cradle-to-gate carbon negative carpet tile.

Defining the Term: Cradle-to-gate

A product’s environmental impact from raw material extraction to the point it leaves the factory gate.

Further, we have followed the blueprint of creating carbon negative carpet tile to do the same in our rubber portfolio. In January we released a prototype rubber product that also holds more carbon in the body of its materials that was emitted to produce it, from the entire supply chain through the manufacturing process.

All of this innovation work helped us step up and lead our industry further when we announced our commitment to eliminate our reliance on carbon offsets. This step helps us chart our path to becoming a carbon negative enterprise by 2040, relying entirely on absolute emission elimination and carbon storage. Our innovation strategy, product design, and investments will all align to this 2040 goal, putting us on the trajectory of becoming a regenerative business.

Absolute emission elimination and carbon storage represent Interface’s path to become a carbon negative enterprise, rather than relying on carbon offsets.

WDM: Please provide more specifics on Interface’s focus on reduction rather than offsets.

Mikhail Davis: With the launch of the Embodied Beauty Collection in 2020, which included the industry’s first commercially available cradle-to-gate carbon negative carpet tiles, we realized our capacity to go further than neutralizing our carbon footprint. We can actually store more carbon in the body of the materials with which we manufacture than is emitted in the entire supply chain and manufacturing process. The achievement of carbon negative carpet tile opened new possibilities for the company to help restore and heal the climate with our own products.

We know the world can’t wait for pollution and carbon emissions to be addressed by offset projects at a later date. We need to emit less now, and store carbon everywhere we can.

The world needs companies to address climate change with the urgency and authenticity the moment demands. This means keeping all the focus on what matters most: reductions and storage, not offsets.

A Carbon Negative Carpet Tile

WDM: Tell us about Interface’s carbon negative carpet tiles. Explain how they can be carbon negative, the technology needed to bring them to market and what’s next.

Mikhail Davis: By adding additional “concentrated carbon” material to our CQuest™Bio backing, we can make a specialty backing (“CQuest™BioX”) that brings the carbon footprint of the entire carbon tile (including yarn, etc.) below zero. We sourced the carbon negative materials from abundant bio-based waste streams from other industries, including agriculture, paper manufacturing and logistics. The next frontier we recently crossed into with a supplier is capturing carbon emissions from industry and using them to create new materials.

But these new carbon storing materials alone would not make our products carbon negative; we also need to use recycled materials and renewable energy and reduce waste and emissions through the process of converting raw materials into finished flooring.

This includes the purchase of 100% renewable electricity for every Interface manufacturing site in the world and sourcing 82% of the yarn we use annually from waste nylon (including textiles, fishing nets, plastic film and post-consumer carpet).

The goal now is to scale up our ability to offer carbon negative products throughout our product portfolio. Only by making most of our product carbon negative can we reach our goal of becoming a Carbon Negative Enterprise by 2040. In service of this goal, we just unveiled our first carbon negative resilient flooring product, a prototype made by our nora rubber business.

25 Years of Sustainable Innovation

WDM: Please recap some of your sustainable initiatives, specifically the ReEntry Reclamation Program, measuring and reporting on emissions; developing carbon negative products; and expansion into hard surface flooring with the same environmental commitments.

Mikhail Davis: The 2040 target to be a carbon negative enterprise is a company-wide goal, so our carbon accounting needs to be comprehensive and inform our decisions across our value chain and throughout our operations. Our carbon reporting, both for investor-focused groups like CDP (Carbon Disclosure Project) and for our own annual Impact Report, is sophisticated and thorough, covering all key areas of our scope 3 emissions profile in addition to our direct emissions (scope 1) and energy and utility-related emissions (scope 2). https://www.interface.com/US/en-US/sustainability/recycling

Defining the Term: CDP (Carbon Disclosure Project)

Independent environmental disclosure system to manage environmental impacts

ReEntry, one of the only third-party verified takeback and recycling programs in the industry, is a key part of our sustainability mission. We take the responsibility we have for our products seriously, from the supply chain phases to the installation and maintenance all the way through to the renovation cycle. It’s important to us to bring product back when we can and recycle it into new product. Our capacity to recycle carpet tile to use in new products and our focus on sourcing recycled content from many sources for our products is crucially important to reducing our emissions and our dependence on virgin raw material.

The lessons we have learned from ReEntry on the carpet tile side, and from a focus on circularity in our business over the last 25 years have carried over into product design and development for the resilient portfolio as well. Our SoundChoice LVT is now standard with 39% recycled content, and our rubber portfolio continues to evolve to include more recycled content and carbon storing materials. In fact, we launched a prototype rubber product that is cradle-to-gate carbon negative at the BAU tradeshow in Germany just three months ago.

From recycling to carbon storing materials, all of our environmental reporting tracks our progress toward our 2040 carbon negative enterprise goal. We want to be able to demonstrate that companies can compete while redesigning the business model to become a regenerative business at the same time.

Carpet as a Service: An Idea Ahead of its Time

WDM: What can we learn from the Evergreen Service Agreement, for leasing carpet, which can inform the development of future “products as a service.”

Defining the Term: PaaS (Products as a Service)

Business model where customers pay for the use of a product, rather than owning it outright

Mikhail Davis: There are many lessons to be learned from Interface’s Evergreen Service Agreement, which in 1999 was definitely ahead of its time. Experts (including the Harvard Business Review) who studied our program concluded that carpet tile simply does not have enough embedded value to work with a leasing model for most customers. People lease cars, copy machines and construction equipment and other more expensive products very successfully.

It is likely that future circular and service-based models for interiors products will have to include higher-value items like furniture in a lease package.

It is probably not worthwhile to lease your carpet when you are buying everything else, Leasing a complete set of the interiors products you need to outfit a space might be more beneficial. When your office lease ends or you decide to refresh, the products go back to the manufacturer or their leasing partner for reuse or refurbishment.

Interface’s Climate Action through Science Based Target initiative (SBT)

WDM: Please explain the Science Based Target initiative (SBT). Tell us how Interface’s SBT confirmation of Interface’s 2030 greenhouse gas reduction targets work? AND ways Interface has committed to reducing Scope 1, 2 and 3 emissions.

Mikhail Davis: In the past, companies could base their emissions reduction goals on what they thought they could achieve without damaging their business.

Science Based Targets require companies to set a reduction target based on what the world needs your business to do to keep from permanently damaging the stability of the climate system.

Defining the Term: SBT (Science based targets)

Targets align with the Paris Agreement, limiting global warming to 1.5° C above pre-industrial levels.

A company’s SBT must be approved by the Science Based Targets initiative, meaning that it is sufficiently comprehensive (including your supply chain, not just direct emissions), aggressive (substantial reductions by 2030) and absolute (no goals that are based on emissions per unit of production). Interface’s SBT commits us to reduce our direct emissions from manufacturing by an additional 50%, but, more importantly, to reduce the emissions from our supply chain by 50% (both by 2030).

This means finding new suppliers of carbon negative and low carbon materials and helping existing suppliers cut emissions and waste while increasing use of recycled materials and renewable energy. We are already driving innovation in these areas with suppliers that are 8-10X our size. Demanding innovation from our suppliers has always been key to how we meet our goals, but also to how we change the way materials are made for everyone. Today the 100% recycled yarn our partner Aquafil developed for us is used in nylon interiors and apparel products by over 1,700 other brands. But we are still their first and biggest customer for this yarn.

Interface’s Pioneering of Environmental Product Declarations (EPDs)

WDM: Please explain EPD’s (Environmental Product Declarations) and how Interface was the first to pilot them in 2004. How have EPD’s impacted the flooring industry today?

Mikhail Davis: Today you cannot sell a flooring products in many markets without having a 3rd party certified disclosure of your carbon footprint and other environmental impacts in the form of an Environmental Product Declaration (EPD). This is the result of decades of work by Interface staff and others to establish standards and to promote adoption of EPDs.

Defining the Term: EPD (Environmental Product Declarations)

The measurement and reduction of the environmental impact of products and services & reporting in a transparent, verifiable method.

EPDs were initially developed in Europe but Interface led the way in North American as the first company to publish an EPD (2009) and then globally as the first company to have a published EPD for every standard product we sold (2012).

We advocated for the adoption of EPDs in LEED v4 and helped create the first free tool that reads and compares competing products’ EPD data (the Embodied Carbon in Construction Calculator (EC3)). We are excited to see more and more customers using carbon footprint (embodied carbon) as a performance specification.

Quantifying Interface’s Impact

Mikhail Davis: At Interface, we think companies that are truly committed to sustainability need to be willing to stop doing things they know aren’t aligned with their highest levels of ambition.

We have changed our business to eliminate activities and material use that don’t align with the impact we want our business to have.

Here’s a brief list of things that Interface no longer does:

- Dye carpet yarn: committing to 100% solution-dyed yarn (making colored yarn from pre-colored plastic pellets rather than applying dye chemicals to the surface of white yarn) dramatically reduced our water use, wastewater effluents, energy use and solid waste production.

- Use non-renewable electricity in manufacturing: we have purchased 100% renewable electricity for 100% of our factory electricity use every year since 2018. We also use renewable bio-gas in our two biggest factories (US and EU).

- Use PFAS (per- and polyfluoroalkyl substances) for stain/soil resist coating, phthalates, heavy metals, or formaldehyde-based ingredients in our products. We were the first US carpet mill to complete a phase out PFAS and pioneered the use of urea-formaldehyde-free fiberglass. When we entered the LVT market, we raised the bar for commercial LVT by launching product by avoiding all of the above harmful chemicals.

- Sell products that are not certified Low-Emitting Materials (low-VOC emissions): all standard products and approved adhesives must pass 3rd party testing for low emissions.

When Ray Anderson, the founder of Interface, read The Ecology of Commerce, by Paul Hawken in 1994, he re-evaluated his business practices and pursued sustainability. His legacy is one of environmental leadership, demonstrating that sustainability can be both a moral imperative and a business opportunity. That mission to restore the health of the planet guides Interface today.

Want to connect with Interface?

Made for More | Find a Rep | Follow on Instagram | Read Our Blog | Contact Us

This article was created in partnership with Interface. All images are courtesy of Interface.